Click on video for view

-

About Us

Yaman Tekstil which aims to develop and grow in the textile sector, where an innovation emerges every day, is progressing confidently with its experienced staff and stable steps.

Yaman Tekstil, which started out with the principle of "Quality is always trust, trust is always a quality customer potential", has always kept quality and customer satisfaction at the forefront.

As Yaman Tekstil, we continue to provide services without compromising on quality, with our modern infrastructure, technical and management staff with a creative and strategic perspective, by targeting unconditional customer satisfaction in every step taken in the sector since 2011.

-

Our modern and state-of-the-art technology company, which is established in one of the most equipped industrial zones of Bursa. We have a closed area of 11 000 square meters, 118 personnel, 2022 model twisting machines with 37.500 spindle capacity, special air conditioning system, constant 25 ̊C, 55 - 60% humidity, with a monthly production of 400-500 tons, provides its customers with the highest quality yarn twisting service. In order to better serve our portfolio, we can try special yarns in our sample twisting machines that we have set up in our facility and carry out different R&D studies in line with the wishes of our customers. With the special software we have developed in our track, we carefully monitor every step of the twisting process, thus ensuring standardization and minimizing the waste rate. With the laboratory we have established in our facility, we try to prevent all problems that may occur by testing the incoming raw materials and the products produced, and in this way, we serve our customers within the shortest deadlines.

-

As Yaman Tekstil, we always keep our modern infrastructure at a high level and up-to-date by conducting continuous R&D studies with an innovative approach to the sector. Our company is one of the leading companies in the sector with its talented young team who have gained more than 12 years of work experience and expertise, continuous development, and fast and error-free mission. With experience, we always aim for the top among the leading and reliable companies in the yarn twisting industry and we continue to work in that direction.

With the desire to leave a livable world to future generations, with our endless respect for nature and all living things, we apply environmental, economic and social standards in all business processes, and we aim to leave a clean world to the next generations. With our responsible team, we develop and implement waste management strategies for the classification of textile wastes as well as recycling without harming the environment and human health. We are taking firm steps towards our vision that focuses on customer satisfaction, is sustainable, and aims at continuous growth and development. We are working for a bigger, higher quality and better Yaman Tekstil in the coming years.

-

Our VisionOur MissionOur Vision

Our VisionOur MissionOur VisionTo respond in the fastest way by analyzing customer requests correctly in our facility, which has integrated and modern technology and complies with international standards, and at the same time follows the principle of quality first while producing. • To add value to the individuals who make up the society by adopting the principles of reliability, occupational health and safety. • As a leading brand in the sector, to become an exemplary company with production facilities that are sensitive to people and the eTo be a sustainable leader and an exemplary company that increases the dependence of the world on our country in the textile industry by contributing to the progress of the textile industry with our technical infrastructure, by following the sectoral innovations, by customer satisfaction, by our quality that we ensure continuity, by our fast service and by our production capacity.

Our Mission- To respond in the fastest way by analyzing customer requests correctly in our facility, which has integrated and modern technology and complies with international standards, and at the same time follows the principle of quality first while producing.

- To add value to the individuals who make up the society by adopting the principles of reliability, occupational health and safety.

- As a leading brand in the sector, to become an exemplary company with production facilities that are sensitive to people and the environment, aware of sustainability and social responsibility, for a more sustainable world. In addition, we consider sustainability activities, which are key to achieving corporate goals, as a company strategy.

- Contributing to the development of the textile industry, which is the locomotive of the country's economy, by increasing its market share, and also contributing to the increase in employment.

- To respond in the fastest way by analyzing customer requests correctly in our facility, which has integrated and modern technology and complies with international standards, and at the same time follows the principle of quality first while producing.

About Us

Yaman Tekstil which aims to develop and grow in the textile sector, where an innovation emerges every day, is progressing confidently with its experienced staff and stable steps.

Yaman Tekstil, which started out with the principle of "Quality is always trust, trust is always a quality customer potential", has always kept quality and customer satisfaction at the forefront.

As Yaman Tekstil, we continue to provide services without compromising on quality, with our modern infrastructure, technical and management staff with a creative and strategic perspective, by targeting unconditional customer satisfaction in every step taken in the sector since 2011.

Our modern and state-of-the-art technology company, which is established in one of the most equipped industrial zones of Bursa. We have a closed area of 11 000 square meters, 118 personnel, 2022 model twisting machines with 37.500 spindle capacity, special air conditioning system, constant 25 ̊C, 55 - 60% humidity, with a monthly production of 400-500 tons, provides its customers with the highest quality yarn twisting service. In order to better serve our portfolio, we can try special yarns in our sample twisting machines that we have set up in our facility and carry out different R&D studies in line with the wishes of our customers. With the special software we have developed in our track, we carefully monitor every step of the twisting process, thus ensuring standardization and minimizing the waste rate. With the laboratory we have established in our facility, we try to prevent all problems that may occur by testing the incoming raw materials and the products produced, and in this way, we serve our customers within the shortest deadlines.

As Yaman Tekstil, we always keep our modern infrastructure at a high level and up-to-date by conducting continuous R&D studies with an innovative approach to the sector. Our company is one of the leading companies in the sector with its talented young team who have gained more than 12 years of work experience and expertise, continuous development, and fast and error-free mission. With experience, we always aim for the top among the leading and reliable companies in the yarn twisting industry and we continue to work in that direction.

With the desire to leave a livable world to future generations, with our endless respect for nature and all living things, we apply environmental, economic and social standards in all business processes, and we aim to leave a clean world to the next generations. With our responsible team, we develop and implement waste management strategies for the classification of textile wastes as well as recycling without harming the environment and human health. We are taking firm steps towards our vision that focuses on customer satisfaction, is sustainable, and aims at continuous growth and development. We are working for a bigger, higher quality and better Yaman Tekstil in the coming years.

Our Vision

Our Mission

Our Vision

To respond in the fastest way by analyzing customer requests correctly in our facility, which has integrated and modern technology and complies with international standards, and at the same time follows the principle of quality first while producing. • To add value to the individuals who make up the society by adopting the principles of reliability, occupational health and safety. • As a leading brand in the sector, to become an exemplary company with production facilities that are sensitive to people and the eTo be a sustainable leader and an exemplary company that increases the dependence of the world on our country in the textile industry by contributing to the progress of the textile industry with our technical infrastructure, by following the sectoral innovations, by customer satisfaction, by our quality that we ensure continuity, by our fast service and by our production capacity.

Our Mission

- To respond in the fastest way by analyzing customer requests correctly in our facility, which has integrated and modern technology and complies with international standards, and at the same time follows the principle of quality first while producing.

- To add value to the individuals who make up the society by adopting the principles of reliability, occupational health and safety.

- As a leading brand in the sector, to become an exemplary company with production facilities that are sensitive to people and the environment, aware of sustainability and social responsibility, for a more sustainable world. In addition, we consider sustainability activities, which are key to achieving corporate goals, as a company strategy.

- Contributing to the development of the textile industry, which is the locomotive of the country's economy, by increasing its market share, and also contributing to the increase in employment.

-

0Spindle Capacity0 +Years of Experiance

Deeply Expertise

We add value to your yarn with our strong machinery and infrastructure, our experienced team, 12 years of experience and our excitement on the first day.

0m2 Closed Area0 +Staff -

Production

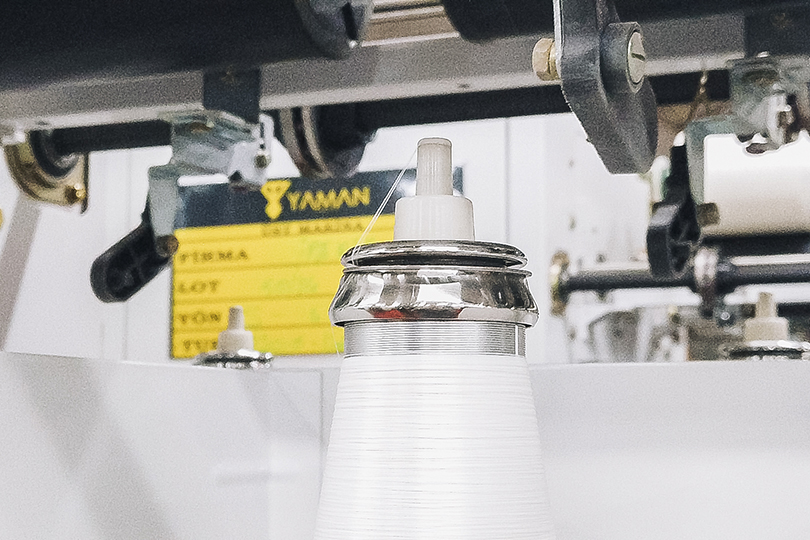

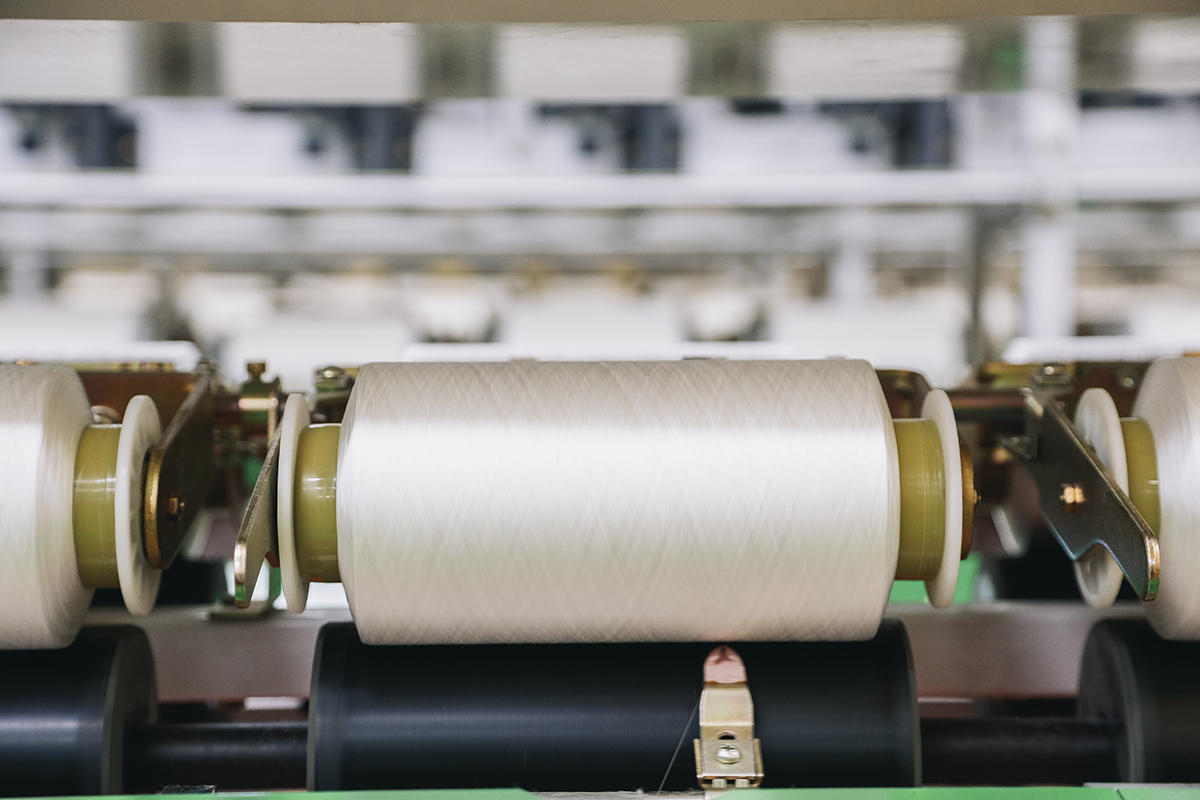

We perform the twisting process of the yarns you sent to our company in our modern facility. We first transfer the yarns to the cops in the transfer machines and make them ready for the twisting process.

Yarn twisting machines with a capacity of 37.500 spindles within Yaman Tekstil provide the highest quality service to its customers with a monthly contract yarn twisting capacity of 500 tons of yarns from 20 denier to 300 denier, floss, polyester, acetate, cupro yarns in the range of 50-3000 turns (TM).

After fixing, which is the last stage of production, the bobbins go through the quality control process one by one, barcode and all products are packaged as shrink to our customers.

-

On Time Delivery

We deliver all products to our customers in the shortest time possible.

Innovative Technology

We follow the industry closely, carry out R&D studies and respond quickly to sample requests with our modern machinery.

Customer Happiness

We operate with a focus on 100% customer satisfaction.

-

Yarn Twisting Process

Transfer process of yarns to our facility

Control and transfer

the yarns to copsTwisting process of the yarns transferred

Fixing process after twisting

Production

We perform the twisting process of the yarns you sent to our company in our modern facility. We first transfer the yarns to the cops in the transfer machines and make them ready for the twisting process.

Yarn twisting machines with a capacity of 37.500 spindles within Yaman Tekstil provide the highest quality service to its customers with a monthly contract yarn twisting capacity of 500 tons of yarns from 20 denier to 300 denier, floss, polyester, acetate, cupro yarns in the range of 50-3000 turns (TM).

After fixing, which is the last stage of production, the bobbins go through the quality control process one by one, barcode and all products are packaged as shrink to our customers.

On Time Delivery

We deliver all products to our customers in the shortest time possible.

Innovative Technology

We follow the industry closely, carry out R&D studies and respond quickly to sample requests with our modern machinery.

Customer Happiness

We operate with a focus on 100% customer satisfaction.

Yarn Twisting Process

Transfer process of yarns to our facility

Control and transfer

the yarns to cops

Twisting process of the yarns transferred

Fixing process after twisting

-

Sustainabilitiy

Did you know that 1 million pet bottles are purchased every minute in the world today? However, only 14% of these plastic bottles are used for recycling and the rest is thrown into the environment.

While it takes an average of 500 years for a plastic bottle to disappear in nature, approximately 8 million tons of plastic is thrown into our oceans annually. While 1 kg of polyester yarn can be made from 80 of these discarded plastic bottles, a t-shirt can be made from 9 plastic bottles, a coat from 70 plastic bottles and a backpack from 40 plastic bottles.

01 kg Polyester Yarn01 T-Shirt01 Backpack01 Coat -

More Livable World to Future

Waste management has become an issue that needs to be brought under control in order to leave a more livable world to future generations. As Yaman Tekstil, we implement waste management systems in our facility. With our environment-friendly team, we separate our wastes resulting from production and use as hazardous and non-hazardous and turn them into reusable raw materials through recycling companies.

To Reduce Water ConsumptionWe are aware that the water resources available in the world are decreasing day by day and the availability of clean water is of critical importance. For this reason, we are constantly improving the infrastructure in our facility in order to reduce water consumption. We take every precaution to reduce water consumption.

To Prefer Energy EfficientWe use water and energy-saving equipment to reduce our carbon footprint, as well as provide consumption controls in water and energy consumption. We prefer energy efficient and environmentally friendly technologies in our investments. In order to prevent the waste of our resources, we use machines with low energy consumption in our facility and we are constantly investigating the possibilities of using green energy resources.

To Improve Awareness of EmployeesAs Yaman Tekstil, we believe that individuals' environmental stewardship will reflect the perspective of institutions. For this reason, we organize continuous trainings in order to improve the environmental awareness of our employees and support them to be more conscious and sensitive in this regard.

In these days when our natural resources are rapidly depleted, one of our biggest goals is to be able to integrate all stages of sustainability with environmental, social and economic dimensions into Yaman Tekstil's DNA. We provide added value to our country by increasing our export figures around the world day by day. Of course, while doing this, our main goal is to leave a clean world to future generations. We care about the protection of nature, and we accept our responsibilities towards nature and all living things as our duty. As Yaman Tekstil, we believe that not only production is important but clean production. For this reason, we reduce our carbon footprint and always aim for sustainable production.

-

Clean Water Sources

We are aware that the available water resources in the world are decreasing day by day and the availability of clean water is of critical importance.

Carbon Footprint

We use water and energy-saving equipment to reduce our carbon footprint, as well as provide consumption controls in water and energy consumption.

Waste Management

Waste management has become an issue that needs to be taken under control in order to leave a more livable world to future generations.

0

Spindle Capacity

0

+

Years of Experience

Deeply Expertise

We add value to your yarn with our strong machinery and infrastructure, our experienced team, 12 years of experience and our excitement on the first day.

0

m2 Closed Area

0

+

Staff

Sustainabilitiy

Did you know that 1 million pet bottles are purchased every minute in the world today? However, only 14% of these plastic bottles are used for recycling and the rest is thrown into the environment.

While it takes an average of 500 years for a plastic bottle to disappear in nature, approximately 8 million tons of plastic is thrown into our oceans annually. While 1 kg of polyester yarn can be made from 80 of these discarded plastic bottles, a t-shirt can be made from 9 plastic bottles, a coat from 70 plastic bottles and a backpack from 40 plastic bottles.

More Livable World to Future

Waste management has become an issue that needs to be brought under control in order to leave a more livable world to future generations. As Yaman Tekstil, we implement waste management systems in our facility. With our environment-friendly team, we separate our wastes resulting from production and use as hazardous and non-hazardous and turn them into reusable raw materials through recycling companies.

To Reduce Water Consumption

We are aware that the water resources available in the world are decreasing day by day and the availability of clean water is of critical importance. For this reason, we are constantly improving the infrastructure in our facility in order to reduce water consumption. We take every precaution to reduce water consumption.

To Prefer Energy Efficient

We use water and energy-saving equipment to reduce our carbon footprint, as well as provide consumption controls in water and energy consumption. We prefer energy efficient and environmentally friendly technologies in our investments. In order to prevent the waste of our resources, we use machines with low energy consumption in our facility and we are constantly investigating the possibilities of using green energy resources.

To Improve Awareness of Employees

As Yaman Tekstil, we believe that individuals' environmental stewardship will reflect the perspective of institutions. For this reason, we organize continuous trainings in order to improve the environmental awareness of our employees and support them to be more conscious and sensitive in this regard.

In these days when our natural resources are rapidly depleted, one of our biggest goals is to be able to integrate all stages of sustainability with environmental, social and economic dimensions into Yaman Tekstil's DNA. We provide added value to our country by increasing our export figures around the world day by day. Of course, while doing this, our main goal is to leave a clean world to future generations. We care about the protection of nature, and we accept our responsibilities towards nature and all living things as our duty. As Yaman Tekstil, we believe that not only production is important but clean production. For this reason, we reduce our carbon footprint and always aim for sustainable production.

0

1 kg Polyester Yarn

0

1 T-Shirt

0

1 Backpack

0

1 Coat

Clean Water Sources

We are aware that the available water resources in the world are decreasing day by day and the availability of clean water is of critical importance.

Carbon Footprint

We use water and energy-saving equipment to reduce our carbon footprint, as well as provide consumption controls in water and energy consumption.

Waste Management

Waste management has become an issue that needs to be taken under control in order to leave a more livable world to future generations.

Contact Us

We would be happy to contact you with any of your comments or questions.s

info@yamanteks.com

+90 224 261 261 7

Kahverengi Cd. No:7 2 D:B, 16140,

Organize Sanayi Bölgesi

Nilüfer / Bursa

Contact Us

We would be happy to contact you with any of your comments or questions.s

info@yamanteks.com

+90 224 261 261 7

Kahverengi Cd. No:7 2 D:B, 16140,

Organize Sanayi Bölgesi

Nilüfer / Bursa